More than 39 Years of Experience

From Sales to After-Sales Service, we ensure that your Projects are completed on Time, within Budget, and to the Highest Quality Standards of the Market.

Click to Go HomeWe Only Use Authentic and High Quality Metal

Services - Premium Stainless Steel Solutions:

Offering a wide range of grades and gauges to meet your needs in durability, corrosion resistance, and aesthetic appeal.

- Square Bars

- Rectangular Bars

- Flat Sheets

- Round Bars

- 202 Grade : A cost-effective alternative to 304, with good corrosion resistance and toughness. It contains lower nickel content, which makes it slightly less corrosion-resistant but more economical.

Often used in budget-conscious construction projects, Great for budget-friendly options like interior partitions, railings, and decorative trim. - 304 Grade : The most versatile and widely used stainless steel. It has excellent forming and welding characteristics, along with strong corrosion resistance.

Ideal for architectural features, handrails, cladding, and structural components that require corrosion resistance and a sleek finish. It’s widely used in building facades, roofing, and decorative elements. - 316 Grade : Known for its enhanced resistance to corrosion, particularly against chlorides and industrial solvents. It’s stronger than 304 and is often used in more demanding environments.

Best for coastal or high-moisture areas, perfect for exterior fixtures, outdoor kitchens, and marine-related structures.

Stainless Steel, Iron, and Galvanised Iron (GI) - Guages We Offer

- 14 Guage

- 16 Guage

- 18 Guage

- 20 Guage

- 14 Guage (2.0mm) : Thick and robust, used in structural supports, heavy-duty enclosures, and other high-stress environments.

- 16 Guage (1.5mm) : Provides increased durability and strength, suitable for heavy-duty applications like structural components, enclosures, and industrial equipment.

- 18 Guage (1.2mm) : Offers a balance between strength and weight, commonly used in kitchen sinks, countertops, and decorative panels.

- 20 Guage (0.9mm) : Thin and flexible, ideal for applications requiring light-weight material with moderate strength structures.

Premium Galvanised Iron Solutions:

We offer high-quality Galvanized Iron (GI) materials, known for their exceptional corrosion resistance and durability.

- What is Galvanised Iron (GI)? :

• GI is an ideal choice for roofing, structural framing, and exterior applications in residential construction. Our GI products ensure log-lasting protection against rust, making them a reliable option for regions with high moisture levels. Available in various gauges and dimensions, our GI materials are designed to meet diverse construction needs while providing excellent value for your investment. - Advantages :

• Corrosion Resistance: GI is coated with zinc, providing superior protection against rust and weathering.

• Durability: With proper installation, GI materials can last for decades, reducing maintenance costs.

• Cost-Effective: GI offers a balance between strength and affordability, making it an economical choice for many construction projects. - Disadvantages :

• Weight: GI is relatively heavier than some other materials, which might require stronger support structures.

• Limited Aesthetic Options: While functional, GI may lack the aesthetic appeal of more decorative materials like stainless steel.

- Authentic & Certified Business

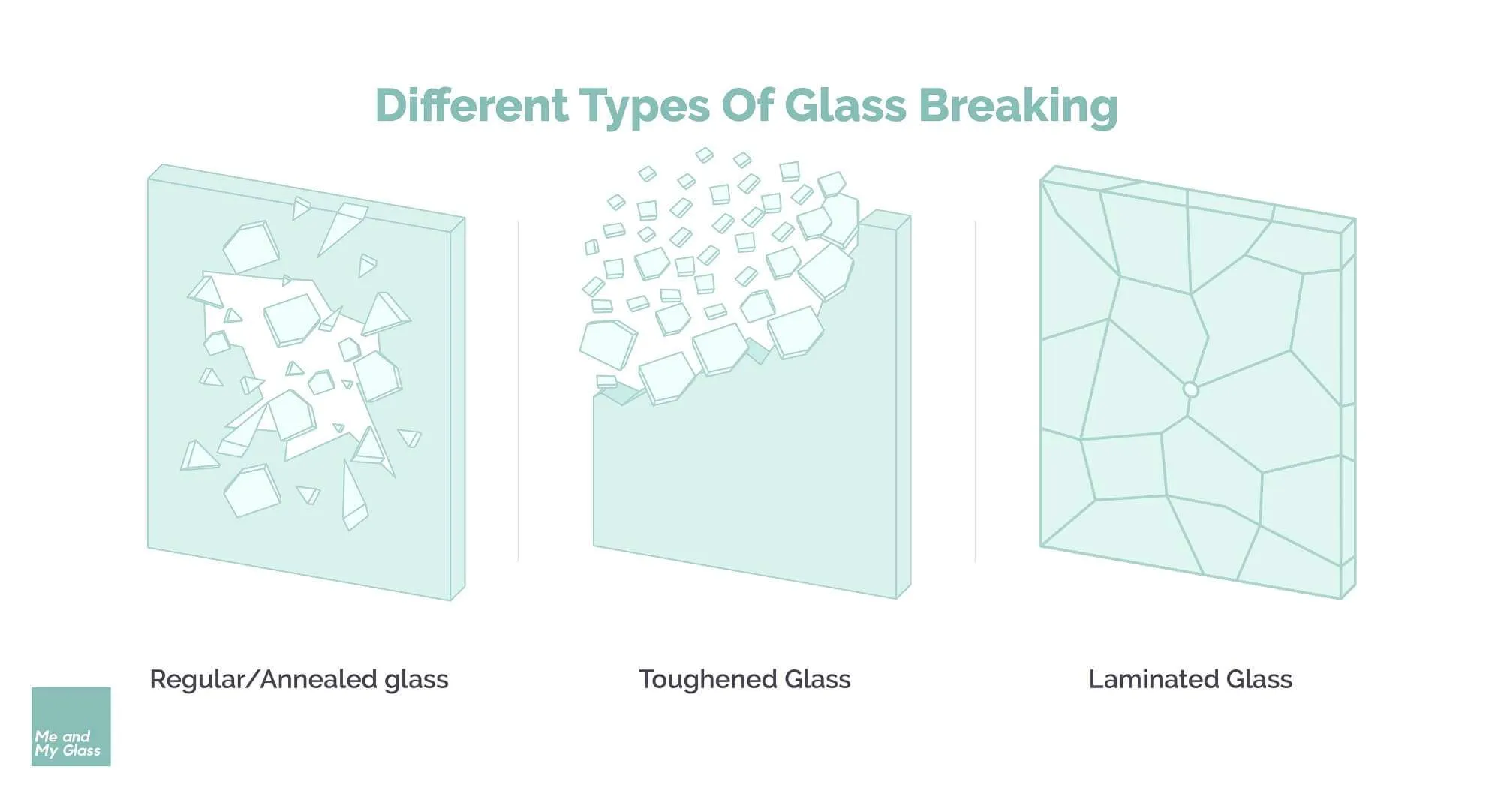

We only use High Quality Toughened Glass for Strength and Safety - Toughened Glass

TOUGHENED Glass is ' 4 X Stronger ' than normal glass of the same size and thickness.

Our culture - Crafting Excellence with Balance.

We are a group of like-minded Professionals who share the same core values.

- Unwavering Commitment. We’re not just a team, we’re a family, dedicated to excellence in every project we undertake.

- Empathy and Understanding. We believe in supporting our team members, knowing that when they thrive, our business thrives. A positive environment is the key to our collective success.

- Relentless Dedication. Our work isn’t just what we do—it’s who we are. We put our heart into every task, ensuring that our passion for quality shines through.

Our Process - How we work

From Design till Delivery

Assess & Plan

We start by closely assessing the project requirements, taking precise measurements and understanding the scope of work. Our team prepares detailed quotations tailored to various quality options, allowing our clients to choose what best suits their needs.

Once the quality is selected, we provide a comprehensive project timeline and communicate all essential details to ensure transparency. Our commitment to quality over profit is evident in everything we do.

we even provide a sample metal piece before starting the work, so you can compare the final product to ensure it meets the same high standards.

Included in this phase

- Detailed site measurements

- Customized quotations for multiple quality options

- Clear communication and timeline setup

- Quality consultation

- Sample metal piece for quality comparison

Design & Manufacture

Upon approval, we secure the necessary raw materials and assign a dedicated team to your project. Our skilled craftsmen then design, develop, and manufacture gates, railings, grills, or other required structures with precision.

Every piece is produced in our state-of-the-art facility, where it undergoes rigorous quality checks and priming to ensure the highest standards of durability and finish.Our focus on quality ensures that every product is built to last.

Included in this phase

- Raw material procurement

- Skilled workforce assignment

- Precision design and development

- Strict quality checks and priming

Deliver & Install

Once the product is ready, we handle the transportation to your project site. Our experienced installation team ensures that the product is fitted with care, meeting all project specifications.

We complete the work with thorough checks and make any necessary adjustments to meet client satisfaction. By providing a sample metal piece at the outset, we ensure that you can trust the quality of the final product—confirming that what we promised is exactly what you received.

Included in this phase

- Safe and timely transportation

- Professional installation and fitting

- Final quality checks and adjustments

- Customer satisfaction guarantee

- Quality verification through comparison with sample metal piece

At Arif Group, Whether you're looking for High-Quality products or expert solutions, our experienced team is extremely dedicated to meeting all your needs with excellence and precision.

Tell us about your project

Our offices

- Arif Metal & Fabrication Works

GST: 36ANRPM3315J1ZP

Near Khammam X road

Nh-65, Suryapet, 508213

Telangana, India - Call Office

+91 9100118221Call President

+91 9394098658

![Phobia,[object Object],Family Fund,[object Object],Unseal,[object Object],Mail Smirk,[object Object]](/_next/static/media/fire.6ad502ab.png)

![Phobia,[object Object],Family Fund,[object Object],Unseal,[object Object],Mail Smirk,[object Object]](/_next/static/media/trade.2abe9bc0.png)

![Phobia,[object Object],Family Fund,[object Object],Unseal,[object Object],Mail Smirk,[object Object]](/_next/static/media/labour.7f273f7d.png)

![Phobia,[object Object],Family Fund,[object Object],Unseal,[object Object],Mail Smirk,[object Object]](/_next/static/media/gst.a6fc4343.png)